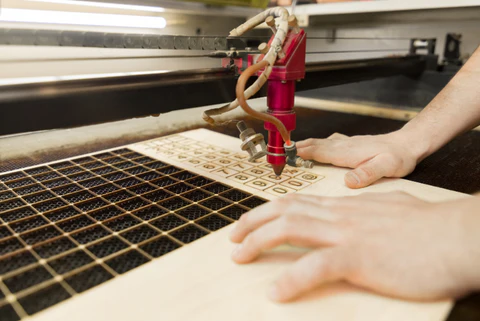

Selecting Suitable Laser Engraving Materials for Your Projects

The success of any engraving project doesn’t just rely on the machine—it also depends on choosing the right laser engraving materials. Whether you’re crafting signage, producing personalized gifts, or designing industrial components, selecting the correct engraving supplies ensures precision, durability, and professional results.

From wood and acrylic to metals, ceramics, and even paper, today’s laser engravers can handle an impressive variety of laser cutting supplies. But each material reacts differently to the laser, so knowing which ones to use—and how to use them—can make or break your project.

In this guide, we’ll cover the most popular laser engraved products by material, explain their unique advantages, and give you practical tips to help you choose the right consumables for your projects.

Why Choosing the Right Laser Engraving Materials Matters

Selecting the correct material is more than a technical choice; it impacts:

- Quality – Different materials produce different contrasts, textures, and finishes.

- Durability – Some engraved products withstand wear, heat, or outdoor conditions better.

- Cost-effectiveness – Using the wrong material leads to wasted engraving supplies and reduced profitability.

- Creativity – Certain materials open new possibilities for customized, unique items.

By understanding how each material interacts with a laser engraving machine, you can expand your product offerings and create stunning results that customers love.

Top Laser Engraving Materials to Consider

Below is a breakdown of the most common and effective laser engraving materials used across industries:

1. Wood

- Why it works: Natural grains create unique textures, making each engraved item one-of-a-kind.

- Best uses: Custom signs, awards, wall décor, furniture accents, and personalized gifts.

- Notes: Softwoods like pine engrave quickly, while hardwoods like oak or maple provide higher contrast.

2. Plywood

- Why it works: Affordable, strong, and widely available.

- Best uses: Prototyping, decorative items, puzzles, and layered art.

- Notes: Choose plywood without excessive glue layers to avoid uneven burning.

3. Bamboo

- Why it works: Eco-friendly, durable, and visually appealing.

- Best uses: Kitchenware, cutting boards, coasters, and fashion accessories.

- Notes: Bamboo engraves darker than most woods, providing strong contrast.

4. Acrylic

- Why it works: Lightweight, durable, and comes in clear, opaque, or colored sheets.

- Best uses: Signage, LED light panels, awards, and jewelry.

- Notes: Clear acrylic engraves frosty white, while colored acrylic creates high-contrast designs.

5. Glass

- Why it works: Produces elegant frosted engravings without compromising transparency.

- Best uses: Wine glasses, trophies, décor items, and awards.

- Notes: A lower power setting prevents cracking or uneven etching.

6. Ceramics & Tiles

- Why it works: Smooth, durable surfaces provide long-lasting engravings.

- Best uses: Customized home décor, coasters, and kitchen products.

- Notes: Ceramic tiles engraved with a laser have sharp contrast ideal for wall art.

7. Leather

- Why it works: Creates a natural burn effect with rich, dark engraving tones.

- Best uses: Wallets, belts, handbags, keychains, and patches.

- Notes: Only use real or laser-safe leather—avoid synthetic materials with PVC.

8. Paper & Cardboard

- Why it works: Cost-effective and versatile for prototyping or creative packaging.

- Best uses: Greeting cards, invitations, packaging, and stencils.

- Notes: Low power settings prevent burning edges.

9. Stone & Slate

- Why it works: Durable, natural material produces permanent, striking engravings.

- Best uses: Memorial plaques, garden stones, coasters, and awards.

- Notes: Engraving typically appears white or light gray against the dark stone.

10. Aluminum Oxide (Anodized Aluminum)

- Why it works: The anodized coating allows for clean, bright engravings.

- Best uses: Business cards, tags, phone cases, industrial labels.

- Notes: Great for precise, high-detail engraving with professional results.

11. Stainless Steel (with Coating)

- Why it works: When pre-coated or treated with marking sprays, stainless steel engraves clearly.

- Best uses: Tools, nameplates, tumblers, and machine parts.

- Notes: Requires higher power or marking agents to achieve strong contrast.

12. Fabric & Textiles

- Why it works: Allows for precision cutting and engraving of natural fabrics.

- Best uses: Felt products, denim designs, cotton apparel, and patches.

- Notes: Avoid synthetic fabrics containing chlorine-based chemicals.

Matching Laser Engraving Materials with Applications

For personalized gifts:

Wood, bamboo, leather, and acrylic are top choices. They offer affordability and visual impact for items like coasters, jewelry, and photo frames.

For signage & branding:

Acrylic and wood remain the most reliable laser cutting supplies thanks to durability and bold visual appeal.

For industrial labeling:

Anodized aluminum and stainless steel stand out as practical choices for long-lasting engraved tags and labels.

For fashion & accessories:

Leather and fabric expand creative opportunities, allowing small studios to produce unique, high-value laser engraved products.

For décor & home goods:

Ceramic tiles, glass, and stone provide professional finishes for household décor items.

Practical Tips for Working with Laser Engraving Materials

- Test before production – Each batch of material can react differently. Run small test engravings to find the right speed and power.

- Focus on safety – Avoid PVC and other unsafe plastics, as they release toxic fumes when engraved.

- Prepare surfaces – Masking tape can help reduce burn marks on wood and acrylic.

- Use proper ventilation – Always work in a well-ventilated space to protect both operator and machine.

- Choose quality supplies – Investing in high-grade engraving supplies reduces waste and improves results.

Expanding Your Business with Laser Engraved Products

The range of laser engraving materials means entrepreneurs can diversify product lines without needing multiple machines. For example:

- Retail shops can create custom gifts like bamboo cutting boards or acrylic keychains.

- E-commerce stores can sell personalized leather wallets or engraved jewelry.

- Signage businesses can produce acrylic LED signs or engraved wooden plaques.

- Industrial companies can engrave metal plates for equipment labeling.

This versatility makes laser engravers a profitable investment, allowing small businesses to deliver custom, scalable, and high-quality products.

Future Trends in Laser Engraving Materials

As technology evolves, so do materials. Expect to see:

- Eco-friendly supplies – More demand for bamboo, recycled paper, and sustainable woods.

- Composite materials – Blends of plastics and natural fibers designed for engraving.

- Advanced coatings – Special treatments for metals and ceramics that improve engraving clarity.

- Lighter yet durable options – Materials optimized for both strength and portability in products.

Businesses that adapt to these trends will stay ahead in offering innovative laser engraved products.

FAQs

Q1. What is the most popular material for laser engraving?

Wood and acrylic are the most widely used due to affordability, ease of use, and versatility.

Q2. Can all metals be engraved with a laser?

Not all. Stainless steel and anodized aluminum work well, but bare reflective metals require special treatments or more powerful lasers.

Q3. Are laser engraved products durable?

Yes. Engravings on wood, metal, glass, and stone are permanent, while items like paper or fabric may wear faster depending on use.

Q4. What materials should I avoid?

Avoid PVC and certain plastics, as they release harmful chlorine gas when cut or engraved.

Q5. How do I choose the right material for my project?

Consider your product’s purpose, desired appearance, and durability needs. Testing small samples helps refine your choice.

Conclusion

Choosing the right laser engraving materials is the foundation of producing high-quality, profitable laser engraved products. From wood and acrylic to metal, glass, and stone, each material offers unique advantages. With the right engraving supplies and a reliable machine, your creative possibilities are endless.

By understanding how materials respond to your laser engraver, you can expand your business offerings, cut production costs, and deliver products that impress your customers. Whether you’re making signage, fashion items, or industrial components, selecting suitable laser cutting supplies ensures success in every project.